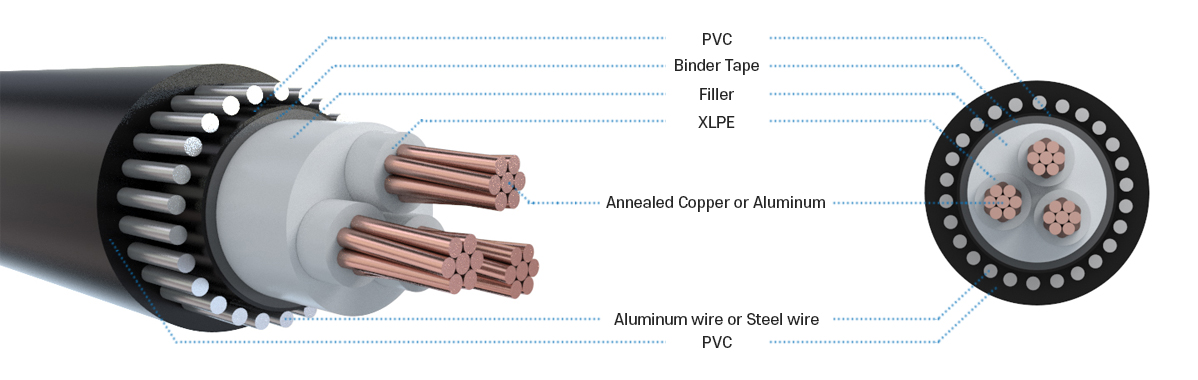

0.6/1kV CU(AL)/XLPE/PVC IEC 60502-1, AS/NZS 5000.1

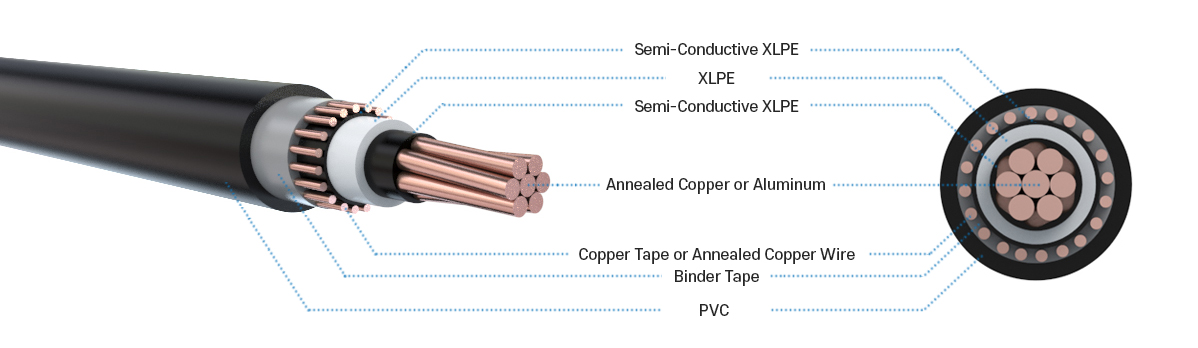

Single Core XLPE Cable

| Conductor | Thickness of Insulation |

Thickness of Sheath |

Approx. Overall Diameter |

Approx. Weight |

||

|---|---|---|---|---|---|---|

| Nominal Crolss-sectional Area |

No. & Dia. of Wire or Shape |

Diameter | ||||

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎜ | ㎏/㎞ |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.4 | 6.5 | 70 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.4 | 7.0 | 80 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.4 | 8.0 | 110 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.4 | 8.5 | 150 |

| 16 | Compact round stranded |

4.7 | 0.7 | 1.4 | 9.5 | 215 |

| 25 | 5.9 | 0.9 | 1.4 | 11.5 | 315 | |

| 35 | 6.9 | 0.9 | 1.4 | 12.0 | 415 | |

| 50 | 8.1 | 1.0 | 1.4 | 13.0 | 555 | |

| 70 | 9.8 | 1.1 | 1.4 | 15.0 | 780 | |

| 95 | 11.4 | 1.1 | 1.5 | 17.0 | 1,025 | |

| 120 | 12.9 | 1.2 | 1.5 | 18.5 | 1,270 | |

| 150 | 14.4 | 1.4 | 1.6 | 21.5 | 1,575 | |

| 185 | 15.9 | 1.6 | 1.6 | 23 | 1,930 | |

| 240 | 18.3 | 1.7 | 1.7 | 26 | 2,470 | |

| 300 | 20.5 | 1.8 | 1.8 | 28 | 3,100 | |

| 400 | 23.2 | 2.0 | 1.9 | 32 | 4,090 | |

| 500 | 26.4 | 2.2 | 2.0 | 36 | 5,100 | |

| 630 | 30.2 | 2.4 | 2.2 | 40 | 6,410 | |

* Approx. Weight data applied copper conductor

Multi Core XLPE Cable

| Conductor | Thickness of Insulation |

Twin Core | Three Core | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Sectional Area |

Number & Diameter of Wire |

Diameter | Sheath Thickness |

Approx. Overall Diameter |

Approx. Weight |

Sheath Thickness |

Approx. Overall Diameter |

Approx. Weight |

|

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎜ | ㎏/㎞ | ㎜ | ㎜ | ㎏/㎞ |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 11.5 | 155 | 1.8 | 12.0 | 190 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 12.5 | 195 | 1.8 | 13.5 | 240 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 13.5 | 255 | 1.8 | 15.0 | 320 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 15.5 | 360 | 1.8 | 16.5 | 465 |

| 16 | 4.7 | 0.7 | 1.8 | 17 | 490 | 1.8 | 18.5 | 650 | |

| 25 | 5.9 | 0.9 | 1.8 | 20 | 720 | 1.8 | 22 | 965 | |

| 35 | 6.9 | 0.9 | 1.8 | 22 | 960 | 1.8 | 24 | 1,290 | |

| 50 | 8.1 | 1.0 | 1.8 | 25 | 1,290 | 1.8 | 27 | 1,770 | |

| 70 | 9.8 | 1.1 | 1.8 | 29 | 1,750 | 1.9 | 31 | 2,440 | |

| 95 | 11.4 | 1.1 | 1.9 | 32 | 2,310 | 2.0 | 35 | 3,240 | |

| 120 | 12.9 | 1.2 | 2.0 | 36 | 2,880 | 2.1 | 39 | 4,050 | |

| 150 | 14.4 | 1.4 | 2.2 | 40 | 3,610 | 2.3 | 43 | 5,050 | |

| 185 | 15.9 | 1.6 | 2.3 | 44 | 4,410 | 2.4 | 48 | 6,200 | |

| 240 | 18.3 | 1.7 | 2.5 | 50 | 5,690 | 2.6 | 53 | 7,990 | |

| 300 | 20.5 | 1.8 | 2.6 | 55 | 7,070 | 2.7 | 59 | 9,980 | |

| 400 | 23.2 | 2.0 | - | - | - | 3.0 | 66 | 13,220 | |

* Approx. Weight data applied copper conductor

0.6/1kV CU(AL)/XLPE/PVC/CTS/PVC IEC 60502-1, AS/NZS 5000.1

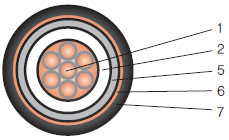

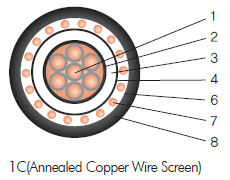

| Cable Design | 1C |  |

||

|---|---|---|---|---|

| 1 | Conductor | Annealed Copper or Aluminum | ||

| 2 | Insulation | XLPE | ||

| 3 | Filler | Filler | ||

| 4 | Tape | Binder Tape | 3C |  |

| 5 | Bedding | PVC | ||

| 6 | Screen | Copper Tape + Binder Tape | ||

| 7 | Sheath | PVC | ||

| Nominal Closs-Sectional Area of Conductor |

Thickness of Insulation | Thickness of Bedding | Thickness of Screen | Thickness of Sheath | Approx. Overall Diameter | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | ||

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎜ | ||||

| 2.5 | 0.7 | - | 1.0 | - | 0.09 | - | 1.8 | - | 14 |

| 4 | 0.7 | - | 1.0 | - | 0.09 | - | 1.8 | - | 15 |

| 6 | 0.7 | - | 1.0 | - | 0.09 | - | 1.8 | - | 16.5 |

| 10 | 0.7 | 1.0 | 1.0 | 0.09 | 0.09 | 1.4 | 1.8 | 11 | 18.5 |

| 16 | 0.7 | 1.0 | 1.0 | 0.09 | 0.09 | 1.4 | 1.8 | 11.5 | 19.5 |

| 25 | 0.9 | 1.0 | 1.0 | 0.09 | 0.09 | 1.4 | 1.8 | 14 | 23.5 |

| 35 | 0.9 | 1.0 | 1.4 | 0.09 | 0.09 | 1.4 | 1.8 | 14.5 | 25.5 |

| 50 | 1.0 | 1.0 | 1.0 | 0.09 | 0.09 | 1.4 | 1.8 | 16 | 28.5 |

| 70 | 1.1 | 1.0 | 1.2 | 0.09 | 0.09 | 1.4 | 2.0 | 17.5 | 33.5 |

| 95 | 1.1 | 1.0 | 1.2 | 0.09 | 0.09 | 1.5 | 2.1 | 19.5 | 40 |

| 120 | 1.2 | 1.0 | 1.2 | 0.09 | 0.09 | 1.6 | 2.2 | 21.5 | 41.5 |

| 150 | 1.4 | 1.0 | 1.4 | 0.09 | 0.09 | 1.6 | 2.4 | 23.5 | 46 |

| 185 | 1.6 | 1.0 | 1.4 | 0.09 | 0.09 | 1.7 | 2.5 | 25.5 | 50.5 |

| 240 | 1.7 | 1.0 | 1.6 | 0.09 | 0.09 | 1.8 | 2.7 | 28 | 56.5 |

| 300 | 1.8 | 1.0 | 1.6 | 0.09 | 0.09 | 1.9 | 2.9 | 30.5 | 62 |

| 400 | 2.0 | 1.2 | 1.8 | 0.09 | 0.09 | 2.0 | 3.2 | 35 | 71 |

| 500 | 2.2 | 1.2 | 1.8 | 0.09 | 0.09 | 2.1 | 3.4 | 38 | 77.5 |

| 630 | 2.4 | 1.2 | 1.8 | 0.09 | 0.09 | 2.3 | 3.8 | 43 | 88 |

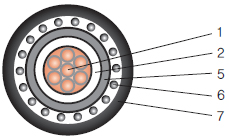

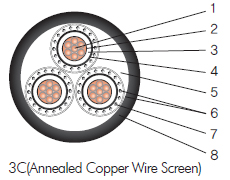

0.6/1kV CU(AL)/XLPE/PVC/SWA(AWA)/PVC IEC 60502-1, AS/NZS 5000.1

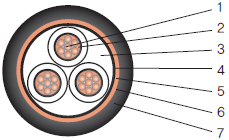

| Cable Design | 1C |  |

||

|---|---|---|---|---|

| 1 | Conductor | Annealed Copper or Aluminum | ||

| 2 | Insulation | XLPE | ||

| 3 | Filler | Filler | ||

| 4 | Tape | Binder Tape | 3C |  |

| 5 | Bedding | PVC | ||

| 6 | Screen | Copper Tape + Binder Tape | ||

| 7 | Sheath | PVC | ||

* single core : Aluminum wire armour, three core : Steel wire armour

| Nominal Closs-Sectional Area of Conductor |

Thickness of Insulation | Thickness of Bedding | Thickness of Screen | Thickness of Sheath | Approx. Overall Diameter | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | ||

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎜ | ||||

| 2.5 | 0.7 | - | 1.0 | - | 0.8 | - | 1.8 | - | 15 |

| 4 | 0.7 | - | 1.0 | - | 1.25 | - | 1.8 | - | 16 |

| 6 | 0.7 | - | 1.0 | - | 1.25 | - | 1.8 | - | 18.5 |

| 10 | 0.7 | 1.0 | 1.0 | 0.8 | 1.25 | 1.8 | 1.8 | 13 | 20.5 |

| 16 | 0.7 | 1.0 | 1.0 | 0.8 | 1.6 | 1.8 | 1.8 | 13.5 | 22.5 |

| 25 | 0.9 | 1.0 | 1.0 | 0.8 | 1.6 | 1.8 | 1.8 | 15 | 26 |

| 35 | 0.9 | 1.0 | 1.0 | 1.25 | 1.6 | 1.8 | 1.8 | 17 | 28.5 |

| 50 | 1.0 | 1.0 | 1.0 | 1.25 | 1.6 | 1.8 | 1.9 | 18 | 31.5 |

| 70 | 1.1 | 1.0 | 1.2 | 1.25 | 2.0 | 1.8 | 2.1 | 20 | 37 |

| 95 | 1.1 | 1.0 | 1.2 | 1.6 | 2.0 | 1.8 | 2.2 | 22.5 | 40.5 |

| 120 | 1.2 | 1.0 | 1.2 | 1.6 | 2.5 | 1.8 | 2.4 | 24 | 46 |

| 150 | 1.4 | 1.0 | 1.4 | 1.6 | 2.5 | 1.8 | 2.5 | 26 | 50.5 |

| 185 | 1.6 | 1.0 | 1.4 | 1.6 | 2.5 | 1.8 | 2.7 | 27.5 | 55 |

| 240 | 1.7 | 1.0 | 1.6 | 1.6 | 2.5 | 1.9 | 2.9 | 30.5 | 61.5 |

| 300 | 1.8 | 1.0 | 1.6 | 2.0 | 2.5 | 2.0 | 3.1 | 33.4 | 66.5 |

| 400 | 2.0 | 1.2 | 1.8 | 2.0 | 3.15 | 2.1 | 3.4 | 38.5 | 77 |

| 500 | 2.2 | 1.2 | 1.8 | 2.0 | 3.15 | 2.2 | 3.6 | 41.5 | 83.5 |

| 630 | 2.4 | 1.2 | 1.8 | 2.5 | 3.15 | 2.4 | 3.9 | 47 | 92.5 |

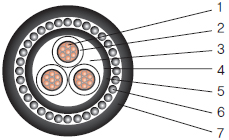

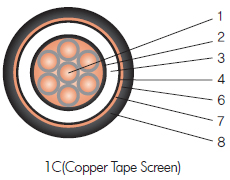

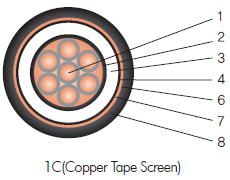

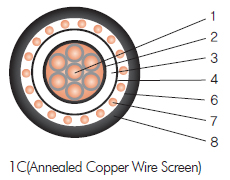

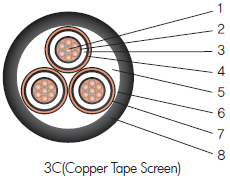

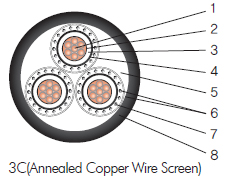

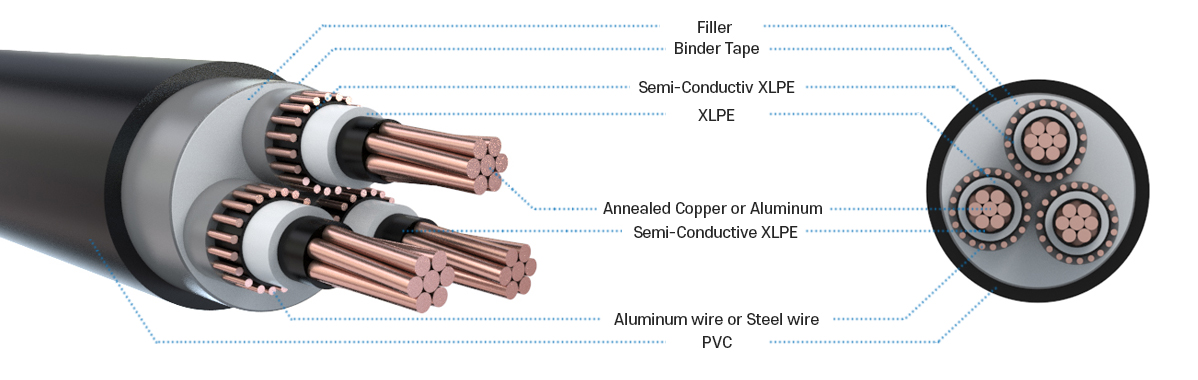

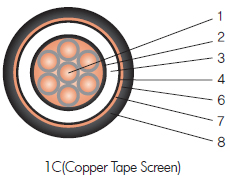

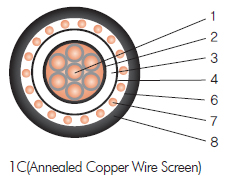

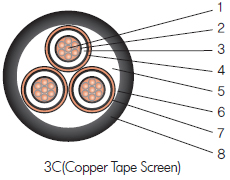

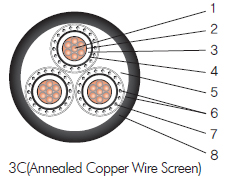

3.6/6(7.2)kV CU(AL)/XLPE/CTS(SCR)/PVC IEC 60502-2

3.8/6.6(7.2)kV CU(AL)/XLPE/CTS(SCR)/PVC AS/NZS 1429.1

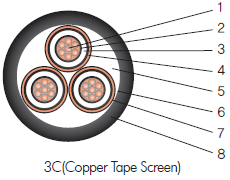

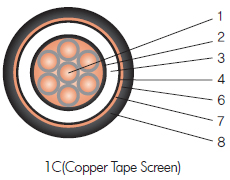

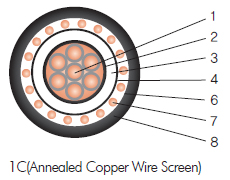

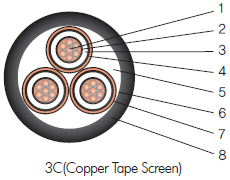

| Cable Design |  |

|

||

|---|---|---|---|---|

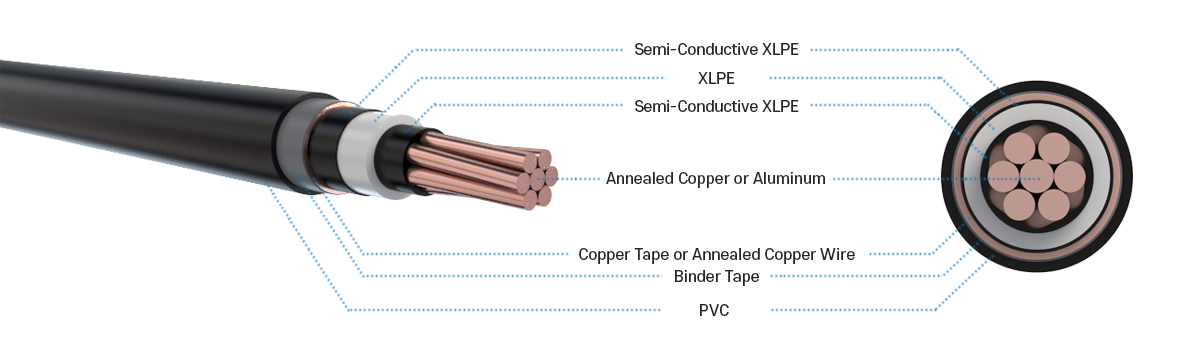

| 1 | Conductor | Annealed Copper or Aluminum | ||

| 2 | Conductor Screen | Semi-Conductive XLPE | ||

| 3 | Insulation | XLPE | ||

| 4 | Insulation Screen | Semi-Conductive XLPE |  |

|

| 5 | Filler | Filler | ||

| 6 | Tape | Binder Tape | ||

| 7 | Metallic Screen | Copper Tape or Annealed Copper Wire | ||

| 8 | Shealth | PVC | ||

* SCR(Annealed Copper Wire Screen) : Up to 10kA fault level

| Nominal Closs-Sectional Area of Conductor |

Thickness of Insulation | Copper Tape Screen | Annealed Copper Wire Screen | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approx. Thickness of Metallic Screen | Thickness Sheath | Approx. Overall Diameter | Nominal Cross-Sectional Area of Metallic Screen | Thickness of Sheath | Approx. Overall Diameter | ||||||||

| 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | ||

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎟ | ㎜ | ㎜ | ||||||

| 16 | 2.5 | 0.1 | 0.1 | 1.4 | 2.0 | 16 | 33 | 16 | 17 | 1.8 | 2.0 | 18 | 35.5 |

| 25 | 2.5 | 0.1 | 0.1 | 1.5 | 2.1 | 17.5 | 36 | 24 | 26 | 1.8 | 2.1 | 19 | 38 |

| 35 | 2.5 | 0.1 | 0.1 | 1.5 | 2.1 | 18.5 | 38.5 | 34 | 34 | 1.8 | 2.2 | 21 | 40 |

| 50 | 2.5 | 0.1 | 0.1 | 1.5 | 2.2 | 19.5 | 41 | 49 | 49 | 1.8 | 2.3 | 22 | 42.5 |

| 70 | 2.5 | 0.1 | 0.1 | 1.6 | 2.4 | 21.5 | 47 | 68 | 68 | 1.8 | 2.4 | 24.5 | 46.5 |

| 95 | 2.5 | 0.1 | 0.1 | 1.6 | 2.5 | 23 | 50.5 | 69 | 69 | 1.8 | 2.5 | 26.5 | 50.5 |

| 120 | 2.5 | 0.1 | 0.1 | 1.7 | 2.7 | 25 | 54.5 | 69 | 69 | 1.8 | 2.7 | 27.5 | 54.5 |

| 150 | 2.5 | 0.1 | 0.1 | 1.7 | 2.8 | 26.5 | 58 | 69 | 69 | 1.8 | 2.8 | 28.5 | 57.5 |

| 185 | 2.5 | 0.1 | 0.1 | 1.8 | 2.9 | 28 | 61.5 | 69 | 69 | 1.9 | 2.9 | 30.5 | 61.5 |

| 240 | 2.5 | 0.1 | 0.1 | 1.9 | 3.1 | 30.5 | 66.5 | 69 | 69 | 2.1 | 3.1 | 33.5 | 67 |

| 300 | 2.5 | 0.1 | 0.1 | 2.0 | 3.2 | 33 | 71 | 69 | 69 | 2.1 | 3.3 | 36.5 | 74 |

| 400 | 2.5 | 0.1 | 0.1 | 2.1 | 3.5 | 36.5 | 79 | 69 | 69 | 2.2 | 3.5 | 40 | 81.5 |

When Aluminum conductor is applied, Annealed Copper Wire Screen data can be changed.

6/10(12)kV CU(AL)/XLPE/CTS(SCR)/PVC IEC 60502-2

6.35/11(12)kV CU(AL)/XLPE/CTS(SCR)/PVC AS/NZS 1429.1

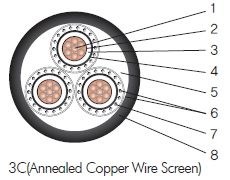

| Cable Design |  |

|

||

|---|---|---|---|---|

| 1 | Conductor | Annealed Copper or Aluminum | ||

| 2 | Conductor Screen | Semi-Conductive XLPE | ||

| 3 | Insulation | XLPE | ||

| 4 | Insulation Screen | Semi-Conductive XLPE |  |

|

| 5 | Filler | Filler | ||

| 6 | Tape | Binder Tape | ||

| 7 | Metallic Screen | Copper Tape or Annealed Copper Wire | ||

| 8 | Shealth | PVC | ||

* SCR(Annealed Copper Wire Screen) : Up to 10kA fault level

| Nominal Closs-Sectional Area of Conductor |

Thickness of Insulation | Copper Tape Screen | Annealed Copper Wire Screen | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approx. Thickness of Metallic Screen | Thickness Sheath | Approx. Overall Diameter | Nominal Cross-Sectional Area of Metallic Screen | Thickness of Sheath | Approx. Overall Diameter | ||||||||

| 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | ||

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎟ | ㎜ | ㎜ | ||||||

| 16 | 3.4 | 0.1 | 0.1 | 1.5 | 2.1 | 18 | 36 | 16 | 17 | 1.5 | 2.2 | 19.5 | 39.5 |

| 25 | 3.4 | 0.1 | 0.1 | 1.5 | 2.2 | 19.5 | 39 | 24 | 26 | 1.6 | 2.3 | 20.5 | 42 |

| 35 | 3.4 | 0.1 | 0.1 | 1.5 | 2.3 | 20.5 | 41.5 | 34 | 34 | 1.6 | 2.4 | 22.5 | 44.5 |

| 50 | 3.4 | 0.1 | 0.1 | 1.6 | 2.4 | 22 | 44 | 49 | 49 | 1.7 | 2.5 | 24 | 47 |

| 70 | 3.4 | 0.1 | 0.1 | 1.7 | 2.5 | 23.5 | 48 | 68 | 68 | 1.8 | 2.6 | 26.5 | 51 |

| 95 | 3.4 | 0.1 | 0.1 | 1.7 | 2.6 | 25 | 51.5 | 69 | 69 | 1.8 | 2.7 | 27.5 | 55 |

| 120 | 3.4 | 0.1 | 0.1 | 1.7 | 2.7 | 27 | 55 | 69 | 69 | 1.9 | 2.8 | 29.5 | 58.5 |

| 150 | 3.4 | 0.1 | 0.1 | 1.8 | 2.8 | 28.5 | 59 | 69 | 69 | 1.9 | 3.0 | 30.5 | 62 |

| 185 | 3.4 | 0.1 | 0.1 | 1.9 | 2.9 | 30 | 63 | 69 | 69 | 2.0 | 3.1 | 32.5 | 66 |

| 240 | 3.4 | 0.1 | 0.1 | 2.0 | 3.0 | 32.5 | 67.5 | 69 | 69 | 2.1 | 3.2 | 35 | 71 |

| 300 | 3.4 | 0.1 | 0.1 | 2.0 | 3.1 | 35 | 72 | 69 | 69 | 2.2 | 3.4 | 38 | 77 |

| 400 | 3.4 | 0.1 | 0.1 | 2.2 | 3.5 | 38.5 | 83 | 69 | 69 | 2.3 | 3.7 | 41 | 84 |

When Aluminum conductor is applied, Annealed Copper Wire Screen data can be changed.

12/20(24)kV CU(AL)/XLPE/CTS(SCR)/PVC IEC 60502-2

12.7/22(24)kV CU(AL)/XLPE/CTS(SCR)/PVC AS/NZS 1429.1

| Cable Design |  |

|

||

|---|---|---|---|---|

| 1 | Conductor | Annealed Copper or Aluminum | ||

| 2 | Conductor Screen | Semi-Conductive XLPE | ||

| 3 | Insulation | XLPE | ||

| 4 | Insulation Screen | Semi-Conductive XLPE |  |

|

| 5 | Filler | Filler | ||

| 6 | Tape | Binder Tape | ||

| 7 | Metallic Screen | Copper Tape or Annealed Copper Wire | ||

| 8 | Shealth | PVC | ||

* SCR(Annealed Copper Wire Screen) : Up to 10kA fault level

| Nominal Closs-Sectional Area of Conductor |

Thickness of Insulation | Copper Tape Screen | Annealed Copper Wire Screen | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approx. Thickness of Metallic Screen | Thickness Sheath | Approx. Overall Diameter | Nominal Cross-Sectional Area of Metallic Screen | Thickness of Sheath | Approx. Overall Diameter | ||||||||

| 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | ||

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎟ | ㎜ | ㎜ | ||||||

| 16 | 5.5 | 0.1 | 0.1 | 1.6 | 2.4 | 21 | 46 | 16 | 17 | 1.7 | 2.5 | 24 | 50 |

| 25 | 5.5 | 0.1 | 0.1 | 1.7 | 2.5 | 24 | 48.5 | 24 | 26 | 1.7 | 2.6 | 25.5 | 53 |

| 35 | 5.5 | 0.1 | 0.1 | 1.7 | 2.6 | 25 | 51 | 34 | 34 | 1.8 | 2.7 | 27 | 54.5 |

| 50 | 5.5 | 0.1 | 0.1 | 1.7 | 2.7 | 26 | 54 | 49 | 49 | 1.9 | 2.8 | 28.5 | 57 |

| 70 | 5.5 | 0.1 | 0.1 | 1.8 | 2.8 | 28 | 57.5 | 69 | 69 | 1.9 | 2.9 | 30 | 60.5 |

| 95 | 5.5 | 0.1 | 0.1 | 1.9 | 2.9 | 30 | 61.5 | 69 | 69 | 2.0 | 3.0 | 32.5 | 65 |

| 120 | 5.5 | 0.1 | 0.1 | 1.9 | 3.0 | 31.5 | 64.5 | 69 | 69 | 2.0 | 3.2 | 34 | 68.5 |

| 150 | 5.5 | 0.1 | 0.1 | 2.0 | 3.1 | 33 | 68 | 69 | 69 | 2.1 | 3.3 | 35.5 | 72 |

| 185 | 5.5 | 0.1 | 0.1 | 2.0 | 3.2 | 34.5 | 71.5 | 69 | 69 | 2.1 | 3.4 | 37 | 76 |

| 240 | 5.5 | 0.1 | 0.1 | 2.1 | 3.4 | 37 | 77 | 69 | 69 | 2.2 | 3.6 | 40 | 81.5 |

| 300 | 5.5 | 0.1 | 0.1 | 2.2 | 3.6 | 39.5 | 82.5 | 69 | 69 | 2.3 | 3.8 | 42.5 | 87.5 |

| 400 | 5.5 | 0.1 | 0.1 | 2.3 | 3.8 | 42.5 | 88.5 | 69 | 69 | 2.4 | 4.0 | 45.5 | 94 |

When Aluminum conductor is applied, Annealed Copper Wire Screen data can be changed.

18/30(36)kV CU(AL)/XLPE/CTS(SCR)/PVC IEC 60502-2

19/33(36)kV CU(AL)/XLPE/CTS(SCR)/PVC AS/NZS 1429.1

| Cable Design |  |

|

||

|---|---|---|---|---|

| 1 | Conductor | Annealed Copper or Aluminum | ||

| 2 | Conductor Screen | Semi-Conductive XLPE | ||

| 3 | Insulation | XLPE | ||

| 4 | Insulation Screen | Semi-Conductive XLPE |  |

|

| 5 | Filler | Filler | ||

| 6 | Tape | Binder Tape | ||

| 7 | Metallic Screen | Copper Tape or Annealed Copper Wire | ||

| 8 | Shealth | PVC | ||

* SCR(Annealed Copper Wire Screen) : Up to 10kA fault level

| Nominal Closs-Sectional Area of Conductor |

Thickness of Insulation | Copper Tape Screen | Annealed Copper Wire Screen | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approx. Thickness of Metallic Screen | Thickness Sheath | Approx. Overall Diameter | Nominal Cross-Sectional Area of Metallic Screen | Thickness of Sheath | Approx. Overall Diameter | ||||||||

| 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | 1C | 3C | ||

| ㎟ | ㎜ | ㎜ | ㎜ | ㎜ | ㎟ | ㎜ | ㎜ | ||||||

| 16 | 8.0 | 0.1 | 0.1 | 1.8 | 2.8 | 28 | 57.5 | 16 | 17 | 1.9 | 2.9 | 29.5 | 61.5 |

| 25 | 8.0 | 0.1 | 0.1 | 1.8 | 2.9 | 29 | 60 | 24 | 26 | 1.9 | 3.0 | 31 | 64.5 |

| 35 | 8.0 | 0.1 | 0.1 | 1.9 | 3.0 | 30.5 | 62.5 | 34 | 34 | 2.0 | 3.1 | 33 | 66.5 |

| 50 | 8.0 | 0.1 | 0.1 | 1.9 | 3.0 | 31.5 | 65 | 49 | 49 | 2.0 | 3.2 | 34 | 69 |

| 70 | 8.0 | 0.1 | 0.1 | 2.0 | 3.2 | 33.5 | 69 | 69 | 69 | 2.1 | 3.3 | 36 | 73 |

| 95 | 8.0 | 0.1 | 0.1 | 2.0 | 3.3 | 35 | 73 | 69 | 69 | 2.2 | 3.4 | 38 | 77 |

| 120 | 8.0 | 0.1 | 0.1 | 2.1 | 3.4 | 37 | 76.5 | 69 | 69 | 2.2 | 3.6 | 39.5 | 81 |

| 150 | 8.0 | 0.1 | 0.1 | 2.1 | 3.5 | 38.5 | 80 | 69 | 69 | 2.3 | 3.7 | 41.5 | 84.5 |

| 185 | 8.0 | 0.1 | 0.1 | 2.2 | 3.6 | 40 | 83 | 69 | 69 | 2.3 | 3.8 | 43 | 88.5 |

| 240 | 8.0 | 0.1 | 0.1 | 2.3 | 3.8 | 42.5 | 89 | 69 | 69 | 2.4 | 4.0 | 45.5 | 94 |

| 300 | 8.0 | 0.1 | 0.1 | 2.3 | 4.0 | 45 | 94 | 69 | 69 | 2.5 | 4.2 | 48 | 99.5 |

| 400 | 8.0 | 0.1 | 0.1 | 2.4 | 4.2 | 47.5 | 100 | 69 | 69 | 2.6 | 4.4 | 51.5 | 106 |

When Aluminum conductor is applied, Annealed Copper Wire Screen data can be changed.