0.6/1kV XLPE insulated FR-PVC sheathed cable in tray (0.6/1kV TFR-CV)

Usage

- This cable is designed for the purpose of using in power distribution line or control system under AC 0.6/1kV, having excellent electrical, physical and chemical and flame retardant properties

Applied specification

- Electrical appliance safety standard, KWS-410

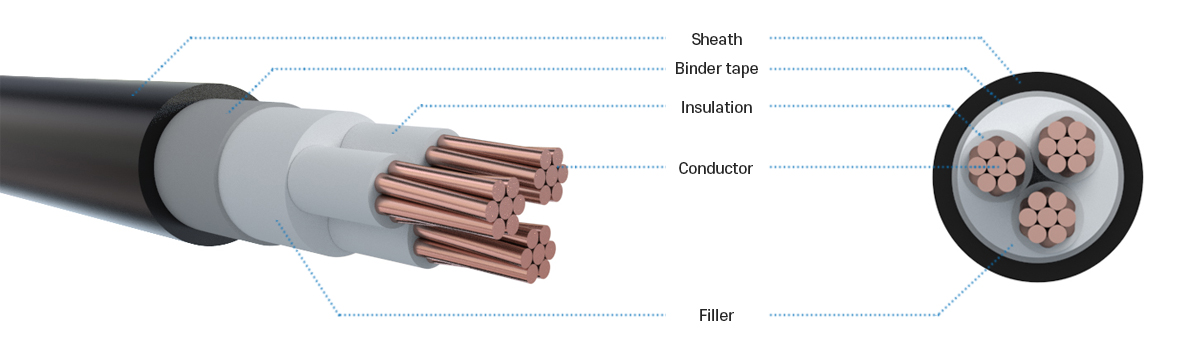

Structure

- Conductor : Annealed copper wire (Concentric circular, Compact circular)

- Insulation : XLPE/FR-XLPE

- Core identification : Coluoring method (2 cores black, white / 3 cores black, white, red / 4 cores black, white, red, green)

- Sheath : PVC/FR-PVC

Single Core

| Conductor | Insulation Thickness |

Sheath Thickness |

Approx. Overall Diameter |

Max. Conductor Resistance at 20℃ |

Test Voltage | Approx. Weight |

Standard Length |

||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Sectional Area |

Number & Diameter of Wire |

Outer Diameter |

|||||||

| ㎟ | No./㎜ | ㎜ | ㎜ | ㎜ | ㎜ | Ω/㎞ | V/5min | ㎏/㎞ | m |

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.4 | 6.3 | 12.1 | 3,500 | 60 | 300 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.4 | 6.7 | 7.41 | 3,500 | 70 | 300 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.4 | 7.2 | 4.61 | 3,500 | 80 | 300 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.4 | 7.8 | 3.08 | 3,500 | 110 | 300 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.4 | 9.4 | 1.83 | 3,500 | 150 | 300 |

| 16 | C.C. | 4.7 | 0.7 | 1.4 | 10.0 | 1.15 | 3,500 | 215 | 300 |

| 25 | C.C. | 5.9 | 0.9 | 1.4 | 12.0 | 0.727 | 3,500 | 315 | 300 |

| 35 | C.C. | 6.9 | 0.9 | 1.4 | 13.0 | 0.524 | 3,500 | 415 | 300 |

| 50 | C.C. | 8.1 | 1.0 | 1.4 | 14.5 | 0.387 | 3,500 | 555 | 300 |

| 70 | C.C. | 9.8 | 1.1 | 1.4 | 16.0 | 0.268 | 3,500 | 780 | 300 |

| 95 | C.C. | 11.4 | 1.1 | 1.5 | 18.5 | 0.193 | 3,500 | 1,025 | 300 |

| 120 | C.C. | 12.9 | 1.2 | 1.5 | 20 | 0.153 | 3,500 | 1,270 | 300 |

| 150 | C.C. | 14.4 | 1.4 | 1.6 | 22 | 0.124 | 3,500 | 1,575 | 300 |

| 185 | C.C. | 15.9 | 1.6 | 1.6 | 24 | 0.0991 | 3,500 | 1,930 | 200 |

| 240 | C.C. | 18.3 | 1.7 | 1.7 | 27 | 0.0754 | 3,500 | 2,470 | 200 |

| 300 | C.C. | 20.5 | 1.8 | 1.8 | 30 | 0.0601 | 3,500 | 3,100 | 200 |

| 400 | C.C. | 23.2 | 2.0 | 1.9 | 34 | 0.0470 | 3,500 | 4,090 | 150 |

| 500 | C.C. | 26.4 | 2.2 | 2.0 | 37 | 0.0366 | 3,500 | 5,100 | 150 |

| 630 | C.C. | 30.2 | 2.4 | 2.2 | 42 | 0.0283 | 3,500 | 6,410 | 150 |

Note) C.C. : Compact round stranded conductor.

Two Cores

| Conductor | Insulation Thickness |

Sheath Thickness |

Approx. Overall Diameter |

Max. Conductor Resistance at 20℃ |

Test Voltage | Approx. Weight |

Standard Length |

||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Sectional Area |

Number & Diameter of Wire |

Outer Diameter |

|||||||

| ㎟ | No./㎜ | ㎜ | ㎜ | ㎜ | ㎜ | Ω/㎞ | V/5min | ㎏/㎞ | m |

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 11.0 | 12.1 | 3,500 | 130 | 300 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 12.0 | 7.41 | 3,500 | 155 | 300 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 13.0 | 4.61 | 3,500 | 195 | 300 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 14.0 | 3.08 | 3,500 | 255 | 300 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 17.0 | 1.83 | 3,500 | 360 | 300 |

| 16 | C.C. | 4.7 | 0.7 | 1.8 | 18.5 | 1.15 | 3,500 | 490 | 300 |

| 25 | C.C. | 5.9 | 0.9 | 1.8 | 22 | 0.727 | 3,500 | 720 | 300 |

| 35 | C.C. | 6.9 | 0.9 | 1.8 | 24 | 0.524 | 3,500 | 960 | 300 |

| 50 | C.C. | 8.1 | 1.0 | 1.8 | 27 | 0.387 | 3,500 | 1,290 | 300 |

| 70 | C.C. | 9.8 | 1.1 | 1.9 | 31 | 0.268 | 3,500 | 1,750 | 300 |

| 95 | C.C. | 11.4 | 1.1 | 1.9 | 35 | 0.193 | 3,500 | 2,310 | 300 |

| 120 | C.C. | 12.9 | 1.2 | 2.0 | 38 | 0.153 | 3,500 | 2,880 | 300 |

| 150 | C.C. | 14.4 | 1.4 | 2.2 | 43 | 0.124 | 3,500 | 3,610 | 300 |

| 185 | C.C. | 15.9 | 1.6 | 2.3 | 47 | 0.0991 | 3,500 | 4,410 | 200 |

| 240 | C.C. | 18.3 | 1.7 | 2.5 | 53 | 0.0754 | 3,500 | 5,690 | 200 |

| 300 | C.C. | 20.5 | 1.8 | 2.6 | 58 | 0.0601 | 3,500 | 7,070 | 200 |

Three Cores

| Conductor | Insulation Thickness |

Sheath Thickness |

Approx. Overall Diameter |

Max. Conductor Resistance at 20℃ |

Test Voltage | Approx. Weight |

Standard Length |

||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Sectional Area |

Number & Diameter of Wire |

Outer Diameter |

|||||||

| ㎟ | No./㎜ | ㎜ | ㎜ | ㎜ | ㎜ | Ω/㎞ | V/5min | ㎏/㎞ | m |

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 11.5 | 12.1 | 3,500 | 150 | 300 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 12.5 | 7.41 | 3,500 | 190 | 300 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 13.5 | 4.61 | 3,500 | 240 | 300 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 14.5 | 3.08 | 3,500 | 320 | 300 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 18.0 | 1.83 | 3,500 | 465 | 300 |

| 16 | C.C. | 4.7 | 0.7 | 1.8 | 19.5 | 1.15 | 3,500 | 650 | 300 |

| 25 | C.C. | 5.9 | 0.9 | 1.8 | 23 | 0.727 | 3,500 | 965 | 300 |

| 35 | C.C. | 6.9 | 0.9 | 1.8 | 25 | 0.524 | 3,500 | 1,290 | 300 |

| 50 | C.C. | 8.1 | 1.0 | 1.8 | 29 | 0.387 | 3,500 | 1,770 | 300 |

| 70 | C.C. | 9.8 | 1.1 | 1.9 | 33 | 0.268 | 3,500 | 2,440 | 300 |

| 95 | C.C. | 11.4 | 1.1 | 2.0 | 37 | 0.193 | 3,500 | 3,240 | 300 |

| 120 | C.C. | 12.9 | 1.2 | 2.1 | 41 | 0.153 | 3,500 | 4,050 | 300 |

| 150 | C.C. | 14.4 | 1.4 | 2.3 | 46 | 0.124 | 3,500 | 5,050 | 300 |

| 185 | C.C. | 15.9 | 1.6 | 2.4 | 50 | 0.0991 | 3,500 | 6,200 | 200 |

| 240 | C.C. | 18.3 | 1.7 | 2.6 | 57 | 0.0754 | 3,500 | 7,900 | 200 |

| 300 | C.C. | 20.5 | 1.8 | 2.7 | 62 | 0.0601 | 3,500 | 9,980 | 200 |

Four Cores

| Conductor | Insulation Thickness |

Sheath Thickness |

Approx. Overall Diameter |

Max. Conductor Resistance at 20℃ |

Test Voltage | Approx. Weight |

Standard Length |

||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Sectional Area |

Number & Diameter of Wire |

Outer Diameter |

|||||||

| ㎟ | No./㎜ | ㎜ | ㎜ | ㎜ | ㎜ | Ω/㎞ | V/5min | ㎏/㎞ | m |

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 12.5 | 12.1 | 3,500 | 180 | 300 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 13.5 | 7.41 | 3,500 | 230 | 300 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 14.5 | 4.61 | 3,500 | 310 | 300 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 16.0 | 3.08 | 3,500 | 400 | 300 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 20 | 1.83 | 3,500 | 585 | 300 |

| 16 | C.C. | 4.7 | 0.7 | 1.8 | 22 | 1.15 | 3,500 | 820 | 300 |

| 25 | C.C. | 5.9 | 0.9 | 1.8 | 26 | 0.727 | 3,500 | 1,245 | 300 |

| 35 | C.C. | 6.9 | 0.9 | 1.8 | 28 | 0.524 | 3,500 | 1,660 | 300 |

| 50 | C.C. | 8.1 | 1.0 | 1.9 | 32 | 0.387 | 3,500 | 2,220 | 300 |

| 70 | C.C. | 9.8 | 1.1 | 2.0 | 36 | 0.268 | 3,500 | 3,110 | 300 |

| 95 | C.C. | 11.4 | 1.1 | 2.1 | 42 | 0.193 | 3,500 | 4,210 | 300 |

| 120 | C.C. | 12.9 | 1.2 | 2.3 | 46 | 0.153 | 3,500 | 5,310 | 300 |

| 150 | C.C. | 14.4 | 1.4 | 2.4 | 51 | 0.124 | 3,500 | 6,330 | 300 |

| 185 | C.C. | 15.9 | 1.6 | 2.6 | 56 | 0.0991 | 3,500 | 7,850 | 200 |

| 240 | C.C. | 18.3 | 1.7 | 2.8 | 63 | 0.0754 | 3,500 | 10,040 | 200 |

| 300 | C.C. | 20.5 | 1.8 | 3.0 | 70 | 0.0601 | 3,500 | 12,620 | 200 |